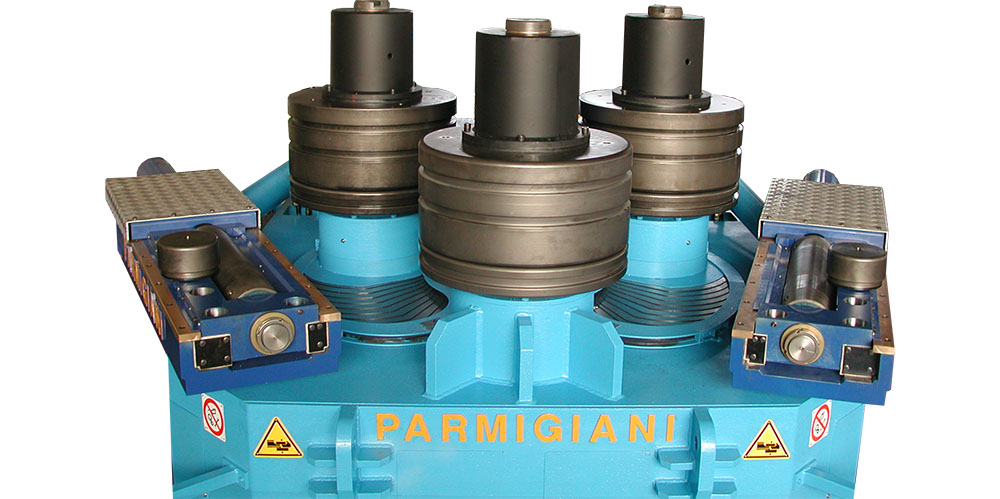

PLANET Series Universal Section Bending Machines

PLANET Technology

More power, more technology.

The PLANET machines perfectly marry power and technology to give you superior performance.

The PLANET section bending machine design combine a solid frame with the most advanced technological innovations which make it simply unrivaled as far as power, ease of operation, efficiency, maintenance-free and long life are concerned.

Rigid frame construction

without forces transmitted

to foundations

Full frame design for maximum rigidity and precision

Operator’s panel with 7” wide screen High resolution full color display, touch – screen

Centralized control panel, light weight design for easy handling

N° 2 Lateral guiding rolls, each one adjustable in 6 directions

Rolls special design that allows fast production and easy handling even in respect of the tightest bending tolerance.

Hydraulic adjustment of the two lower rolls independent of each other (double prebending).

N° 3 driving rolls (all).

Fully hydraulic drive of top and lower rolls with speed compensation

Universal bending rolls in High Tensile alloyed Forged Steel, head treated.

Control panel with low voltage control designed for "easy-service"

Shaft in alloyed steel (heat treated), mounted on long life grease lubricated self-alignment spherical roller bearings.

Each guiding roll is complete of rolls for bending angle-iron leg-in.

Two rolls: one for small and one for the larger sizes angles.

More precise - More productive

Ergonomic panel - Touch controls

Bigger, brighter and easier to learn and operate.

The Generation DiGIMATIC features fast adjustment of machine functions and controls and is integrated into the centralized panel to create a seamless control center. The DiGIMATIC control features a 7-inch touchscreen display and is standard equipment on almost all models of Planet angle rolls.

Increasing productivity and bending precision

are key elements to become more profitable

More power - More torque

HTT System High transmitted torque

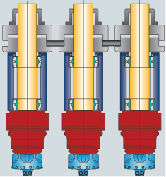

The three hydraulic motors that drive the rolls, are specially interconnected (by our HTT exclusive system) in order to obtain the best speed compensation (related at profile size and bending radius) and distribution of the couple on each roll during the bending operation.

The rolls driving is realized by independent hydraulic motors via planetary gear transmission directly coupled to each driven roll.

The independent rolls hydraulic drive assures an optimal distribution of the torque on each roll during the working phase.

The HTT system allow the best plate feeding and the highest driving torque of any competitive machine. A winning combination for those looking for performance of the highest level.

Best speed compensation

Infinitely variable rolling speeds

Protection of the profile and of the rolls surface

More flexible - More versatile

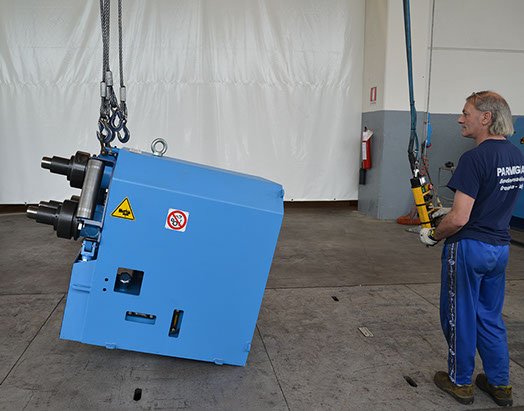

Combined design

VERTICAL + HORIZONTAL

standard up to model Planet 45

The powerful and reliable choice

Full frame extended design

The most heavily sized frame you can find in the market.

Unlikely slim frames covered with thin thickness plates that you can find on all machines in the market our frame design looks definitively oversized.

The exclusive full frame design withstands all bending forces and guarantees stiffness and performances through the years.

This unique machine frames, with extended design for added rigidity and strength, are welded fabrication.

After welding all frames are stress relieved and then machined on cnc milling machines.

Quick Links

Products

About us

Copyright © 2016 PARMIGIANI MACCHINE. All Rights Reserved.

World

Headquarters

PARMIGIANI MACCHINE

Via Sesto, 44

26100 Cremona

Italy

Tel +39 0372 216.39

Fax +39 0372 457.814

E-mail:

info(at)parmigiani.net

One name. One Family. One Company. Since 1927.