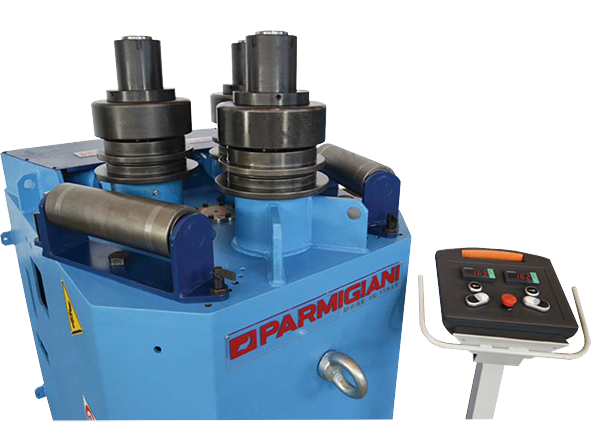

PLANET 15-B Angle roll - Section bending machine

PLANET 15-B

FEATURES

OPTIONS

TECHNOLOGY

CAPACITY METRIC

■ Machine combined design, for working with vertical and horizontal axis.

■ N° 3 driving rolls (all).

■ Fully hydraulic drive:

Rolls driven by low speed hydraulic motor + planetary reduction gear.

■ Hydraulic adjustment of the two lower rolls independent of each other

(double prebending).

■ Hydraulic unit with pilot operated check valves to maintain constant the lower rolls position during bending-phase.

■ All welded steel frame, monobloc type for added strength and rigidity, stress relieved after welding.

■ Shaft in alloyed high-strength chrome-nickel forged steel (heat treated), mounted on long life grease lubricated self-alignment spherical roller bearings.

■ Bending rolls in High Tensile alloyed Forged Steel, heat treated.

■ N° 2 Lateral guiding rolls, each one adjustable in four directions.

■ Total protection from overloads by hydraulic pressure relief valves.

■ Electric and Hydraulic equipment by first class European manufacturers.

■ Centralized control panel with low voltage control designed for "easy-service", portable

to permit optimum location for operator convenience and safety.

■ Control panel with push button controls for all functions.

■ Device for spiralling or coiling of pipes and tubes with tooling for calibration of pitch and coils diameter .

■ CNC controls: FAST or STRADIVARI.

■ Rolls for pipes.

■ Rolls for square and rectangular tubes.

■ Rolls for rolling sections to diameters smaller than attainable with standard rolls.

■ Rolls for special shape sections.

■ Calibrating devices for repetitive works, accurate spiralling and coiling.

■ Elongated shafts for rolling wider sections.

■ Hydraulic pushing roll device to keep angle leg-in and leg-out (and other sections) firmly against the top roll.

■ High rolling speed for rolls rotation (turbo speed).

■ Special operating voltage or special electrics.

MOBILE AND PORTABLE CONTROL PANEL

WITH TWO ELECTRONIC DIGITAL READOUTS

• 02 electronic digital readouts for the two adjustable rolls position

• Push button controls for rolls rotation

• Push button controls for rolls the two lower rolls adjustment

• Emergency stop control

FULL FRAME EXTENDED DESIGN

The most heavily sized frame you can find in the market.

The exclusive full frame design withstands all bending forces and guarantees stiffness and performances through the years.

This unique machine frames, with extended design for added rigidity and strength, are welded fabrication.

After welding all frames are stress relieved and then machined on cnc milling machines.

FULL HYDRAULIC DRIVE SYSTEM

Fully hydraulic drive: Rolls driven by low speed hydraulic motor + planetary reduction gear

UNIVERSAL BENDING ROLLS

The machine is equipped with a complete set of high resistance forged steel universal bending rolls for rolling all standard sections: angle iron leg-in and leg-out, T-bar leg-in and leg-out, square bar, flat bar on-flat and on-edge, rectangular and square tube as well as Channels, I and H-beams on the easy-way (y-y axis).

FOUR-DIRECTIONAL GUIDE ROLLS

Four- directional operated lateral guiding rolls with axial thrust and angular tilting mechanically operated with fast adjustment system.

Quick Links

Products

About us

Copyright © 2016 PARMIGIANI MACCHINE. All Rights Reserved.

World

Headquarters

PARMIGIANI MACCHINE

Via Sesto, 44

26100 Cremona

Italy

Tel +39 0372 216.39

Fax +39 0372 457.814

E-mail:

info(at)parmigiani.net

One name. One Family. One Company. Since 1927.