Parmigiani:

Plate Bending Rolls,

Section Bending Machines,

Dishing and Flanging Machines

Parmigiani:

Plate Bending Rolls,

Section Bending Machines,

Dishing and Flanging Machines

A CENTURY OF EXCELLENCE AND INNOVATION

For close to a century, Parmigiani has been the true fabricator’s choice, designing and manufacturing high-performance dishing and flanging equipment, plate rolls and section bending machines in Cremona, Italy.

Three generations have worked through the decades for the best customer satisfaction, applying the most advanced manufacturing technology in order to improve our end-user quality and productivity.

UNRIVALLED CNC CONTROLS

The NC and CNC controls developed by our in-house software engineers have no equal on the market. Parmigiani offers the widest CNC range to match every application and budget. From our entry-level DIGIMATIC® to our revolutionary STRADIVARI®, you control the entire machine with the touch of a finger.

Accessible and easy to use regardless of the operator’s skill level.

A CENTURY OF EXCELLENCE AND INNOVATION

For close to a century, Parmigiani has been the true fabricator’s choice, designing and manufacturing high-performance dishing and flanging equipment, plate rolls and section bending machines in Cremona, Italy.

Three generations have worked through the decades for the best customer satisfaction, applying the most advanced manufacturing technology in order to improve our end-user quality and productivity.

UNRIVALLED CNC CONTROLS

The NC and CNC controls developed by our in-house software engineers have no equal on the market. Parmigiani offers the widest CNC range to match every application and budget. From our entry-level DIGIMATIC® to our revolutionary STRADIVARI®, you control the entire machine with the touch of a finger.

Accessible and easy to use regardless of the operator’s skill level.

VBH

Advanced 4-roll Plate Bending Rolls

Rolls length from 300 up to 8.000 mm

The VBH is the best machine for both cylindrical and conical bending.

The main features of our VBH rolls are the greater bottom roller pinching force — for short flat ends and optimum pre-bending — and its higher drive torque (for single-pass process) to boost productivity.

A winning combination for those looking for performance of the highest level.

VBH

Advanced 4-roll Plate Bending Rolls

Rolls length from 300 up to 8.000 mm

The VBH is the best machine for both cylindrical and conical bending.

The main features of our VBH rolls are the greater bottom roller pinching force — for short flat ends and optimum pre-bending — and its higher drive torque (for single-pass process) to boost productivity.

A winning combination for those looking for performance of the highest level.

PCO

3-roll Variable Axis Plate Bending Rolls

Rolls length from 1.000 up to 8.000 mm

Highest power, absolute pre-bending precision and maximum flexibility are amongst the main features of our PCO plate rolls.

All three rolls are moving independently from each other: the lower rolls slide along the horizontal axis, whereas the top roll moves vertically.

The peculiar geometry of the PCO roll makes it possible to bend heavy thickness plates just by increasing the centerline distance between the two lower rolls. In this way, it is possible to have a heavy-duty machine but with a smaller frame compared to traditional 3- or 4-roll plate bending rolls.

PCO

3-roll Variable Axis Plate Bending Rolls

Rolls length from 1.000 up to 8.000 mm

Highest power, absolute pre-bending precision and maximum flexibility are amongst the main features of our PCO plate rolls.

All three rolls are moving independently from each other: the lower rolls slide along the horizontal axis, whereas the top roll moves vertically.

The peculiar geometry of the PCO roll makes it possible to bend heavy thickness plates just by increasing the centerline distance between the two lower rolls. In this way, it is possible to have a heavy-duty machine but with a smaller frame compared to traditional 3- or 4-roll plate bending rolls.

PLANET

Universal Section Bending Machines

Models for section modulus up to 18.000 cm³

PLANET section bending machines are the result of almost a century of improvement and innovations, combining sturdy frames with cutting-edge technology.

The PLANET range includes many models to fit any production need. All section benders come with a complete set of standard bending rolls to bend most of common profiles. Their special design avoids any shape deformation of the rolled section and allows fast production and easy handling, complying even with the tightest bending tolerances.

PLANET

Universal Section Bending Machines

Models for section modulus up to 18.000 cm³

PLANET section bending machines are the result of almost a century of improvement and innovations, combining sturdy frames with cutting-edge technology.

The PLANET range includes many models to fit any production need. All section benders come with a complete set of standard bending rolls to bend most of common profiles. Their special design avoids any shape deformation of the rolled section and allows fast production and easy handling, complying even with the tightest bending tolerances.

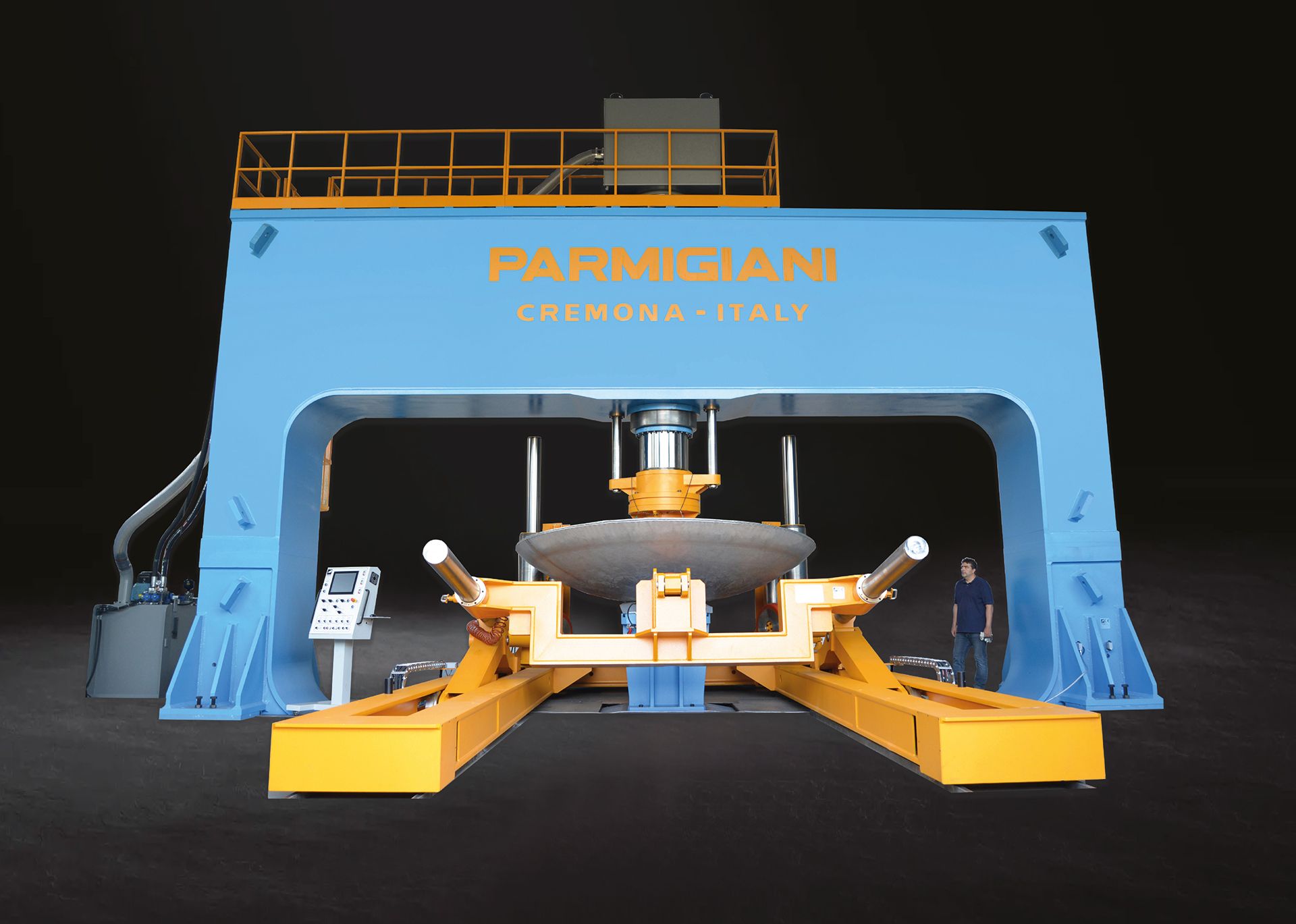

DPO – MAP

Dishing Presses and Automatic Manipulators

Blanks diameter from 300 to 12.000 mm

Parmigiani dishing units are designed to achieve superior speeds and peak performances.

The DPO dishing presses have been engineered and manufactured to ensure the greatest productivity and withstand even the harshest working conditions.

Their large and robust frames, together with cutting-edge technology and premium components, will meet even the highest expectations in terms of working standards.

DPO – MAP

Dishing Presses and Automatic Manipulators

Blanks diameter from 300 to 12.000 mm

Parmigiani dishing units are designed to achieve superior speeds and peak performances.

The DPO dishing presses have been engineered and manufactured to ensure the greatest productivity and withstand even the harshest working conditions.

Their large and robust frames, together with cutting-edge technology and premium components, will meet even the highest expectations in terms of working standards.

FM-Hy

Tank Heads Flanging Machines

Diameters from 200 a 12.000 mm

Our FM-hy series extensive portfolio includes a wide range of models covering the most diverse requirements for the flanging of dished heads.

Regardless of which shape you need to form, FM-hy can solve even the most demanding task: cones, flat and dished heads can be flanged precisely and cost-effectively, always complying with the international standards.

FM-Hy

Tank Heads Flanging Machines

Diameters from 200 a 12.000 mm

Our FM-hy series extensive portfolio includes a wide range of models covering the most diverse requirements for the flanging of dished heads.

Regardless of which shape you need to form, FM-hy can solve even the most demanding task: cones, flat and dished heads can be flanged precisely and cost-effectively, always complying with the international standards.

Applications

We have the perfect machine for every application.

Structures

Storage Tanks

Pressure Vessels

Off-Shore

Power Plants

Aircraft industry

Dished Heads

Heat-Exchangers

Shipyard

Tank Construction

Tankers

Buckets

Wind Towers

Tunnel Mining

Petrochemical

Food & Beverage

Structures

Storage Tanks

Pressure Vessels

Off-Shore

Power Plants

Aircraft industry

Dished Heads

Heat-Exchangers

Shipyard

Tank Construction

Tankers

Buckets

Wind Towers

Tunnel Mining

Petrochemical

Food & Beverage

Contact us for more information or to request a quote