VBH Features

With the VBH Series we exceed your expectations.

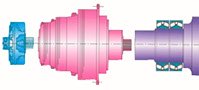

How we exceed your expectations? It’s simple: The all-new VBH Series was created from the belief that every feature, every innovation, must be focused on helping you grow your bottom line. This led our engineers to design the next generation of plate rolls, concentrating on four key areas of machine performance:

STRENGTH: Linear sliding guides and multiple bearings rolls support system.

POWER: High torque reduction unit for reduced number of rolling passes.

PRECISION: Digital control of the rolls parallelism with proportional valves.

CONTROLS: Infinitely variable rolls adjustment speeds, Infinitely variable central lower roll pinching pressure, shell calibration working modes, extended i-diagnostic system... are only some of the features that you can control directly from the operator mobile panel, just moving a finger.

Rigid frame construction

without forces transmitted

to foundations

Full frame design for maximum rigidity and precision

Wired with light-cables

against electromagnetic

interference.

Centralized control panel, light weight design for easy handling

Rolls made of high resistance steel forgings, with large diameter and light cambering

Machine frame with linear guides for rolls sliding

Heavy-duty multibearing system with 4 spherical roller bearings for each roll

Sliding support with high resistance antifriction material

maintenance free

Fully hydraulic drive of top and lower rolls with automatic speed compensation

Instantaneous brakes for rolls rotation for maximum safety factor

Digital control of the rolls parallelism with proportional valves. Precision 0,1 mm (0,004”)

Heavy-duty turning bearing support, with four anti deflection points for maximum rigidity

Infinitely variable pinching pressure of the central lower roll with digital pressure gauge

Heavy-duty and rigid frame design for maximum resistance for cone rolling

Get more with linear guides

ALG System Antifriction Linear Guides

The linear guides design is the only system that can grant the necessary machine stiffness and the perfect geometry for all kind of bending operations.

The linear design allows a compact geometry of the machine ("minimum centerline distance between the two side rolls" impossible to obtain with the swinging design) that it is essential for the bending precision and accuracy.

The linear design allows to work in the best and ideal geometrical conditions when rolling high yield strength materials, reducing the shell spring back reopening effect and also allows to obtain much smaller bending diameters when compared with the swinging design.

No friction - less than swing design

Direct loads to the plate

Less vertical power on top roll

Lower bending diameter

Built for heavy works

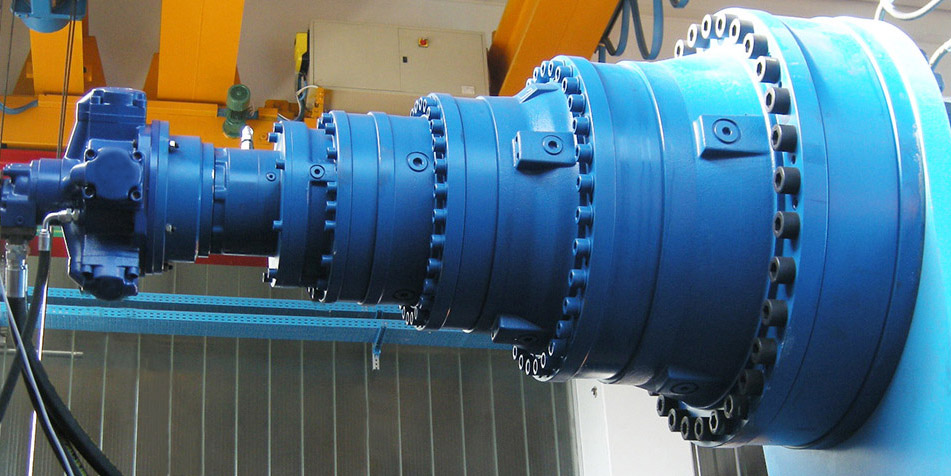

HMB System Heavy Multiple Bearings

Each bending roll is supported by 4 heavy-duty self-aligning spherical roller bearings (double raw type).

Each bearing is oversized in order to withstand the whole bending load.

Thanks to the HMB exclusive design, with four oversized bearings fitted into a swiveling housing, the roll can freely deflects along it’s full width during the rolling process.

This guarantees an optimal distribution of the load on the supports even during the cone rolling process and increase the machine reliability and life.

Moreover, the multi bearing system with swiveling housings design greatly reduces the maintenance and the need for lubrication (permanent lubrication).

The powerful and reliable choice

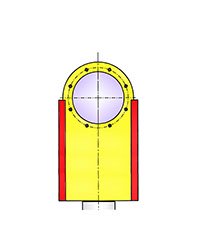

Full frame extended design

The most heavily sized frame you can find in the market.

Unlikely slim frames covered with thin thickness plates that you can find on all machines in the market our frame design looks definitively oversized.

The exclusive full frame design withstands all bending forces and guarantees stiffness and performances through the years.

This unique machine frames, with extended design for added rigidity and strength, are welded fabrication.

After welding all frames are stress relieved and then machined on cnc milling machines.

Friction free - Maintenance free

AST System Anti-friction sliding technology

Each Rolls supports with machined anti-friction material in sliding area.

This system drastically reduce the maintenance and the sliding friction is lower than in a planetary machine.

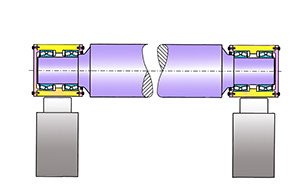

More power - More torque

HTT System High transmitted torque

The rolls driving is realized by independent hydraulic motors via planetary gear transmission directly coupled to each driven roll.

The independent rolls hydraulic drive assures and automatic speed compensation between the top and lower rolls and an optimal distribution of the torque on each roll during the working phase.

The HTT system allow the best plate feeding and the highest driving torque of any competitive machine.

A winning combination for those looking for performance of the highest level.

Quick Links

Products

About us

Copyright © 2016 PARMIGIANI MACCHINE. All Rights Reserved.

World

Headquarters

PARMIGIANI MACCHINE

Via Sesto, 44

26100 Cremona

Italy

Tel +39 0372 216.39

Fax +39 0372 457.814

E-mail:

info(at)parmigiani.net

One name. One Family. One Company. Since 1927.